The key to creating bespoke, hyper-efficient aftermarket solutions for your business

$743 billion

That’s the total value of all retail returns in 2023. According to the National Retail Federation (NRF), it amounts to 14.6% of all purchases that year, illustrating the importance of efficient reverse logistics. Minimizing the costs of returns and maximizing the resale valueis a top priority for retailers and brands across industries.

96%

of returns handled by GXO are returned to stock

That’s where data science can help design custom, hyper-efficient solutions for your business.

More than 170 million returns are processed each year at GXO facilities alone — 96% of which are returned to stock. GXO Direct, GXO’s network of shared warehousing and services, offers a best-in-class, real-time customer portal that provides unmatched supply chain visibility. These insights enable companies to quickly disposition returned products and increase reclamation value.

Value-added services in the supply chain have not only become a major part of a brand’s image but serve a brand promise to fulfil on the expected overall customer experience . Customers buy into a brand and want to know that whatever the outcome of the purchase, the brand is going to make it easy for them to resolve any potential issues.

Efficiency, ownership, tracking and data management can pose major challenges. The driver of those challenges? Every company’s reverse logistics needs are unique — whether due to the volume of product being received, the specs of the products being managed, or the company’s existing tech stack and the limitations that can put on potential solutions. Those circumstances can impact returns, refurbishment, recycling, refund management, warranty claim adjudication and more.

Value-added services in the supply chain have not only become a major part of a brand’s image but serves as a brand promise to fulfil on the expected overall customer experience.

Using data science to identify opportunities for improvement

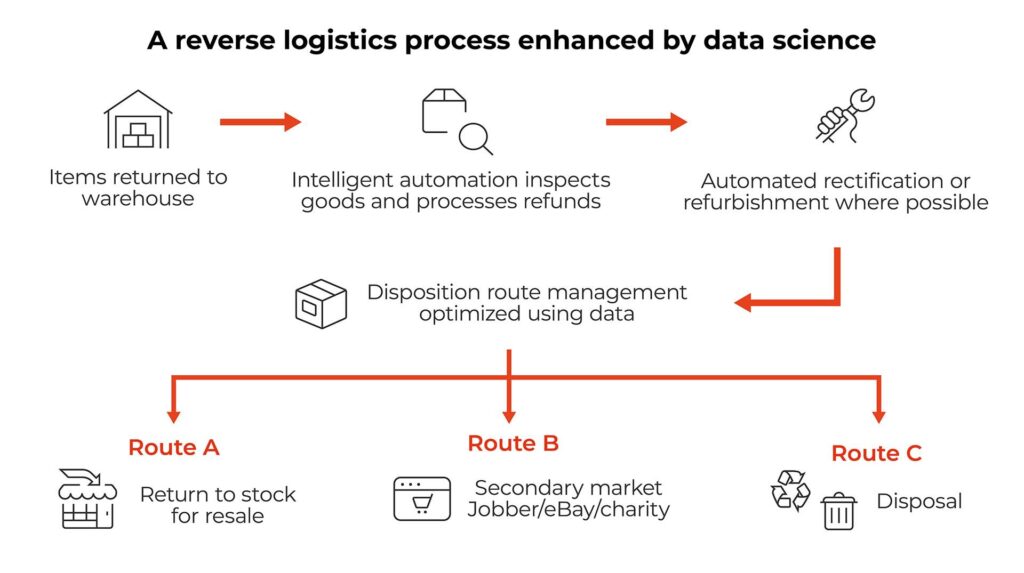

Data science applies a scientific approach to sorting and analyzing large amounts of data. Weaving data science into reverse logistics can result in game-changing efficiencies — efficiencies that help businesses thrive while dealing with changing labor markets, rapid growth, seasonal peaks and shifts in consumer behavior.

Data is raw information, and data science helps spot opportunities amid that data. This approach can uncover historical trends and provide real-time insights, enabling quick, informed decision-making.

That’s why GXO has a dedicated team of applied mathematicians, analysts and programmers who design custom solutions for clients. Informed by real-time data, our team is able to strategically put intelligent automation and machine learning to work.

Data sets might include details of inbound receipts, product inspection information, sorting patterns, refurbishment needs, refund information, ebbs and flows related to seasonality or changing consumer behavior. With the help of machine learning, data science experts can identify points of friction or inefficiencies and design custom solutions to address them.

This could, in the case of personal electronic devices, for example, help inform inspection classifications for returned product(s), so that sortation can be automated and quality can be assured in a way that helps protect the brand. At the same time, it helps to determine the most efficient handling to maximize value recovery, whether that’s through resale, a secondary sales channel, recycling or some other use.

This approach can uncover historical trends and provide real-time insights.

This is just one example of how data science increases the long-term impact of the bespoke systems GXO builds. It’s our major advantage. We’ve helped clients use their data to easily spot trends in return flows, forecast future needs for both staffing and parts management and determine the best areas of focus for automation technology such as pre-programmed sorters or collaborative robots (cobots).

Our systems can help turn returns into your lowest-cost stock. With the combination of data, robotics and automation, we can turn a return into the fastest replenishment to shelf and get the product back into the hands of the customer.

GXO’s data analytics capabilities

People

Data scientists

100+ applied mathematicians, business analysts and programmers

Platform

Fourth-generation data and analytics platform

An added analytical value chain layer

Process

Proven project management process

Customer interviews, process documentation and more, to evaluate and coordinate performance

Solutions

Supply chain optimalisering

Custom solutions, SKU stratification and affinity, transportation optimization and more

Smart solutions for managing (and minimizing) a backlog

The continuous rise in returns can leave businesses struggling to keep up, or worse, facing a backlog. Backlogs not only result in a poor customer experience, but also compound supply chain pressures and add the costs of storage and care if the hope is to get products back onto shelves for customers.

A data-driven approach is vital for solving for this.

Cutting a 1,000-trailer backlog to zero for a footwear manufacturer

By layering data science onto incoming returns information, GXO designed a system that could calculate expected returns, and then prioritize the highest-value products to maximize potential resale.

The data also led to insights that were foundational for automated systems in the manufacturer’s 1+ million-square-foot reverse logistics center. These systems helped employees eliminate the entire backlog and today all returned products are processed within 48 hours — most even faster.

Before GXO

1,000-trailer backlog of returns

After GXO

48-hour turnaround on all returned products

Analysis that reinvigorates refurbishment and repair

Refurbishment and repair can be lucrative components of any reverse logistics solution, from appliances to electronics and beyond. The refurbished market for electronics alone is estimated to be roughly $48 billion in 2023. A primary challenge here is time, as refurbished products need to be returned to market as quickly as possible to maximize value. The quality of the repairs must be reliable — without delivering consistently high-quality products, customers lose trust, which impacts sales and leads to more product waste.

An approach informed by data science can alleviate both concerns, allowing the business to quickly deliver high-quality refurbished products into customers’ hands.

Sorting, refurbishing and processing tens of thousands of units per day for a large electronics provider

For one large electronics provider, GXO consolidated multiple facilities and legacy systems to streamline processes.

Then, insights from return data were used to:

- Develop automated systems to facilitate receipt

- Speed inspection and sorting

- Guide the testing and repair of devices

Tens of thousands of units are now processed per day, all within 24 hours of receipt, including return merchandise authorization forms (RMAs) for vendors. The changes have reduced overall inventory and saved millions of dollars.

Slashing the scrap rate for an appliance manufacturer

GXO helped establish six strategically located facilities to minimize variability in how products were assessed and repaired. Then, GXO data scientists redesigned the refurbishment processes at the facilities and helped automate steps in testing, repackaging, storage and outbound shipments. Data science helped uncover patterns in the types of returns received, as well as in the types of repairs required for those returns.

When we started with the customer, there were 28 approved repairs on returned goods, and the scrap rate was 43%.

With our data analysis and recommended changes, we’ve increased the number of approved repairs to 68 and cut the scrap rate almost in half, to 28%.

The result? Higher-quality repairs and more goods entering secondary sales channels, increasing sales and profitability.

Data-driven processes that prioritize reuse and recycling

Returns sent to disposal account for an estimated 6 billion pounds of waste each year, and many of these products could be diverted from the waste stream. That doesn’t necessarily mean repair or refurbishment; data science can provide insights to allow for complete lifecycle management, including disassembly, reuse and recycling.

Completely eliminating disposal waste for a global printer supplier

GXO implemented one such program with the goal of having zero products end up in disposal. Our data scientists were able to create a system that consolidated the entire reverse logistics operation into a single facility that managed sorting, disassembly, stripping, cleaning, testing for reuse, weighing, registration, preparation for repair or recycling and full management of all waste streams.

More than 90% of these returns were either reused or recycled—and most importantly, no products are diverted to disposals. Similar processes could work for a broad range of industries.

We’re able to identify high-value returns as well as returns with high-value components that can be used in repair or refurbishment. Our focus is on managing returns in the most cost-effective way, which means minimizing waste and maximizing reuse or recycling.

Data is raw information, and data science helps spot opportunities amid that data

On top of that, analysis of the data around returns can help to identify possible issues in manufacturing, guiding upstream changes that reduce problems that lead to returns in the first place.

This could possibly help determine a running change that leads to an improvement and helps protect our customer’s brand.

A data-driven approach to reverse logistics can have a profound impact on your business

Our focus on data science has helped GXO become the world’s largest pure-play contract logistics provider with data informing the solutions GXO creates for every customer, no matter the size, industry or need.