World-class logistics is more accessible than you think

Boost inventory management to lower costs and miles

Turn returns into a profit center

Employ tools like automation without being a tech expert

Scale with a partner but stay focused on you

Bring on top talent without all the overhead

Improve sustainablility with existing infrastructure

Leverage four decades of know-how to own your future

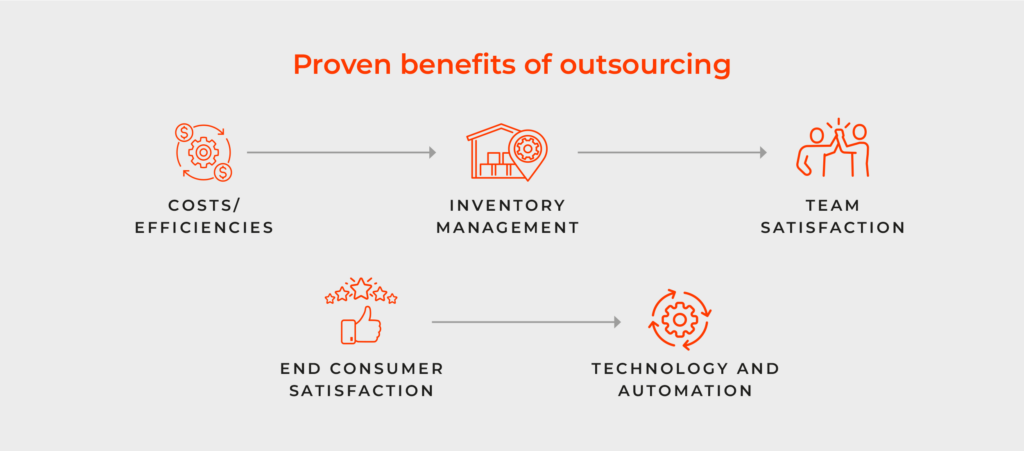

This report explores how outsourcing your logistics can help you make your operations more efficient, more productive, more predictable and more sustainable — making logistics work for you.

Optimized logistics is an increasingly critical part of any great supply chain. If there is anything the past few years have proven, it’s just how important an efficient and resilient supply chain is to short- and long-term business success.

Yet, world-class logistics is not a core competency for most companies. Managing significant logistics in-house can divert management’s focus and financial resources away from its core competencies, adding costly assets and overhead and impeding growth and innovation.

In addition, many companies don’t have the expertise to research, deploy and operate the technology that can optimize their logistics and future-proof their business. Fortunately, even if logistics is not a core competency, the right logistics partner can help you unlock your supply chain’s full potential.

The right partner can assess your operations and design a customized solution such as refurbishing an existing facility or adapting a shared space to help you allocate capital more efficiently and meet the unique needs of your business. The right partner can also guide you on how to:

- Deploy technology and automation to create a competitive advantage

- Put flexible inventory management solutions to use

- Leverage their scale

- Manage business cycles with flexible resourcing

- Transform reverse logistics from a cost center into a means to maximize profit on each returned item and raise customer satisfaction

- Achieve your ESG goals

- Help you de-risk your supply chain, minimizing disruptions and improving your customer satisfaction

OPPORTUNITY 1

Boost inventory management to lower costs and miles

Superior inventory management is one of the key ingredients in a world-class supply chain, but most companies don’t have the expertise to leverage technology or to make data visible to more precisely match supply and demand, enabling a higher proportion of full-priced sales.

Data analytics can help improve inventory management. Data analytics, coupled with a customized Warehouse Management System, can deliver a better overview of inventory across many locations, significantly reducing overstock and boosting margins.

The strategic use of technology is another way to optimize inventory management. Leveraging modular technology can significantly reduce costs and process products faster and more smoothly.

Optimizing inventory management can also involve rationalizing facilities — in some cases, consolidating many sites into one or two strategically located sites — or bringing products closer to end consumers, placing inventory in strategic locations to reduce transportation costs, carbon footprint and delivery times.

Indoor flexibility supports growth for leading outdoor living products company

A leading ecommerce company needed a logistics partner that could support its growth regionally, from fulfilling record orders for the peak summer season to enhancing operations and customer experiences.

GXO’s shared-space distribution network helped the customer expand warehouse operations by more than 300% across three facilities, bringing inventories closer to major population centers.

This in turn reduced fixed costs, cut shipping times and costs, lowered CO2 emissions by reducing shipping miles and provided best-in-class service to more customers coast-to-coast with the flexibility necessary to adapt quickly to changing demand.

OPPORTUNITY 2

Maximize the value of returned products

End-to-end reverse logistics management can be costly, complex and an environmental challenge, with studies showing that in some verticals as many as 25% of returned products end up in landfills.

Yet, returned purchases present a significant opportunity. An expert in reverse logistics can effectively receive and evaluate returns, place them quickly into usable inventory or repair and refurbish them to maximize their resale value. And using data analytics can help predict the volume of returns and even specific items, minimizing unnecessary inventory expansion.

By using advanced scanning and robotic technologies, the right reverse logistics partner can also accelerate processing for returned products, offering items for resale quickly and efficiently —maximizing their in-season retail value.

In addition, the ability to repair or refurbish many returned items helps customers convert those items into higher revenue and profit in cases where returned products otherwise may be bound for landfill. On average, GXO’s returns management helps customers resell more than 96% of returned items, leaving less than 4% to be either donated to charity or recycled.

Improved reverse logistics can drive a nearly 30%increase in revenue from returned products and a 60% increase in gross profits for an omnichannel retailer, which means the right reverse logistics solution will drive profitability and reduce the environmental impact of returns.

Reverse logistics — a good fit for a leading shoe retailer

A leading online shoe retailer needed a partner that could support its rapid growth and its commitment to provide 100% free returns for 100 days following a purchase, without incurring additional expenses.

Together, GXO designed and implemented an over 210,000 square foot, ultra-modern, almost fully automated distribution center that quickly and efficiently processes over 1 million returns annually, meeting the goal for turnaround time at a rate of better than 99%.

OPPORTUNITY 3

Employ tools like automation without being a tech expert

Warehouse technologies can improve productivity and efficiency, increase flexibility to quickly adjust to changes in demand, reduce training time, increase employee safety and engagement and help achieve environmental goals. Companies that have not invested in automation and advanced technology are falling behind, and the pace at which they’re falling behind is accelerating.

But what if you’re not a technology expert? Staying abreast of the latest technological innovations is time-consuming and putting those innovations to their best use takes a lot of expertise and investment. An industry-leader in operational tech deployment, including large-scale automation, robotics, machine learning and AI, like GXO can design the right technology solutions to drive the maximum ROI while enhancing performance visibility with best-in-class, real-time data visualization.

For customers taking advantage of GXO’s technology-driven solutions, the results speak for themselves:

Reduced variable fulfillment costs by 50% or more

Increased team productivity of up to 4x

Improved order accuracy,reduced returns rate

Cut training times by as much as 80%

Reduced excess inventory wastage by 60%

Tech and automation are key to optimizing your supply chain

A large global fashion retailer was struggling with order lead times that weren’t competitive. As a result, its customers ordered through wholesale channels, reducing the company’s margins. GXO’s solution involved integrating a flexible workforce with collaborative robots in a facility that was strategically located to minimize transportation costs and increase speed to market. By deploying collaborative robots, or cobots, that could even operate on a mezzanine extension, GXO drove a 40% reduction in inventory while doubling the number of manageable SKUs in circulation. Variable costs were reduced by more than a third and faster returns processing times, reduced from one week to 48 hours, coupled with next-day delivery, drove a 45% increase in the customer’s Net Promoter Scores.

GXO has approximately 10,000 units of automation technology in operation at sites around the world. Small, flexible modular technology solutions can be retroactively fitted and focused on a specific warehouse process to optimize operations. For example, machine vision tech has driven an approximately 8% increase in processing speed and cobots drive a greater than 200% increase in productivity compared to manual processes.

OPPORTUNITY 4

Scale with a partner but stay focused on you

For many businesses, whether they are an emerging brand or a large global player, scale is indispensable. Supporting strategic growth plans requires a partner that has the scale — geographic, resources and functions (e.g., HR, real estate) —necessary to help achieve your business goals quickly and efficiently.

Scale also provides access to cutting-edge technology that delivers an attractive ROI. Working with a logistics partner that can grow and easily integrate software platforms, implement new automation and robotics and quickly and predictably set up efficient solutions can help derive the greatest benefits from this mission critical part of your supply chain.

Scale is also a way to enhance purchasing power. With roughly 1,000 sites globally, GXO can secure excellent terms for technology and automation and provide ready access to these solutions to enable quick adjustments to changes in demand.

Consolidating operations can save space and money

A global food company was under pressure from rising costs in an inflationary environment, and the margin drag was compounded by order inaccuracy and stock shrinkage.

This customer’s warehouse footprint was comprised of multiple expensive facilities that were entirely manual, which increased their exposure to labor inflation . Additionally, traditional manual processes reduced accuracy and increased inventory wastage, within accurate fulfilment being directed towards discount channels, driving lower margins.

GXO launched a major transformation project that consolidated several entirely manual warehouse operations into a single fully automated facility that increased productivity by 150%, reduced variable costs by 60%, improved picking accuracy and cut inventory wastage by two-thirds. Improved inventory management drove faster turnover of certain product lines.

OPPORTUNITY 5

Bring on top talent without all the overhead

Many companies find it difficult to attract and retain a talented labor pool, making it a challenge to adapt quickly to rapidly changing consumer demand.

A partner that is appealing to a talented, full-time and contract workforce as employers of choice in their local communities is critical. This includes offering a combination of wide-ranging recruiting networks, safe and rewarding working environments, competitive wages and benefits and outstanding development opportunities.

Logistics technologies have many benefits far beyond making operations more productive and cost-effective. They can eliminate repetitive tasks for employees, free them to do more value-added work, enhance their safety, reduce their training times and create a more engaging overall work environment. In addition, the right data analytics can help to forecast customer volumes and identify the right headcount and balance workload.

As an employer of choice with more than 130,000 global team members, GXO has access to workforce resources to meet any staffing needs.

This enables a high degree of flexibility to adjust quickly to match seasonal demand peaks and troughs throughout the year to maximize efficiency.

Working with cutting-edge warehouse and fulfillment technology, our team members are constantly learning and growing help our clients optimize their logistics.

Birds of a feather: Placing businesses with similar peaks together is a win-win

A customer was launching a product into big-box retail outlets and needed a flexible and responsive partner for retail fulfillment.

GXO placed them in a campus environment alongside customers with complementary peak seasons.

Implementing a flexible labor-sharing solution enabled the customer to reduce overhead costs while retaining skilled employees.

OPPORTUNITY 6

Improve sustainability with existing infrastructure

Businesses are under increasing pressure to make their supply chains more sustainable, and making a supply chain more efficient naturally makes it more sustainable.

Creating a more sustainable supply chain is critical to most companies. An experienced and reliable partner can help achieve ESG goals with existing supply chain infrastructure. GXO can help drive sustainability by transforming every aspect of logistics — from reducing unsold inventory and making reverse logistics financially viable to improving safety and enhancing the employee experience, all of which reduce costs to customers and help drive ESG KPIs. Energy- and water efficient warehouses also have the capability to send surplus energy back to the grid and produce “zero waste.”

GXO is an industry leader in ESG, having received an “AA” rating from MSCI and recognition by Newsweek magazine as one of America’s most responsible companies .

GXO’s comprehensive solutions approach can also dramatically reduce transportation costs and CO2 emissions. For example, using real-time data to plan efficient delivery routes; constructing or leasing warehouses near transportation hubs and/or close to a customer’s primary customer base; helping customize packaging to distribute more items per shipment; and increasing order accuracy to reduce returns.

Creating super sustainability for a major supermarket chain

A major supermarket chain tapped GXO to help reduce its environmental footprint for over three thousand stores. GXO introduced new processes to help the customer meet its net-zero carbon target by 2035 through reusing, recycling or sending away products for energy recovery.

A key innovative solution involved changing the cleaning chemical and washing equipment for washing trays, enabling the customer to maintain the same level of quality and hygiene, all with cold water. By reducing energy that would have been used to heat the water, GXO was able to deliver financial and environmental savings to the customer.

Each year, 12 GXO sites operating 24/7/365 and employing a staff of 900 make 1.3 million equipment repairs; wash 260 million trays and more than 11 million flower buckets annually; and handle 280,000 metric tons of cardboard and 21,000 metric tons of plastic waste. Since 2009, the customer has sent zero waste directly to a landfill.

OPPORTUNITY 7

Leverage four decades of know-how to own your future

By outsourcing your logistics to GXO, an industry leader with a proven track record of operational excellence, you put the world’s most technologically advanced contract logistics provider to work for your company.

You can capitalize on GXO’s unique understanding of customer challenges, benefit from insights and best practices from across its global network and leverage expertise developed over four decades to design tailored solutions to address them.

GXO serves companies in a dozen sectors — a wide range that includes Aerospace and defense, Automotive, Food and beverage, Omnichannel retail and Technology and consumer electronics, to name a few.

No matter the size of your company or whether you operate in a single market or around the world, by partnering with GXO, you can unlock the power of logistics at full potential.

Interested in learning more about how outsourcing logistics can help your business?